Technologies and Strengths of the Refrigerated Warehousing Business

YOKOREI is a food infrastructure company that enables a stable supply of high-quality products to the tables of consumers through our Refrigerated Warehousing Business.

Using high-level technology and know-how, we store and manage a wide variety of raw materials and foods, including agricultural, marine, and livestock products, as well as frozen foods, under optimal temperature control.

Refrigerated warehouses are located at key distribution points throughout Japan

Yokorei has three types of refrigerated warehouses (dockside warehouses, logistics centers, and producing area warehouses) to handle a wide range of food storage and logistics needs. In recent years, Yokorei has focused on providing “consolidated multidistribution logistics,” a service unique to Yokorei that combines the functions of an inventory-type distribution center (DC), a transit distribution center (TC), and a delivery center.

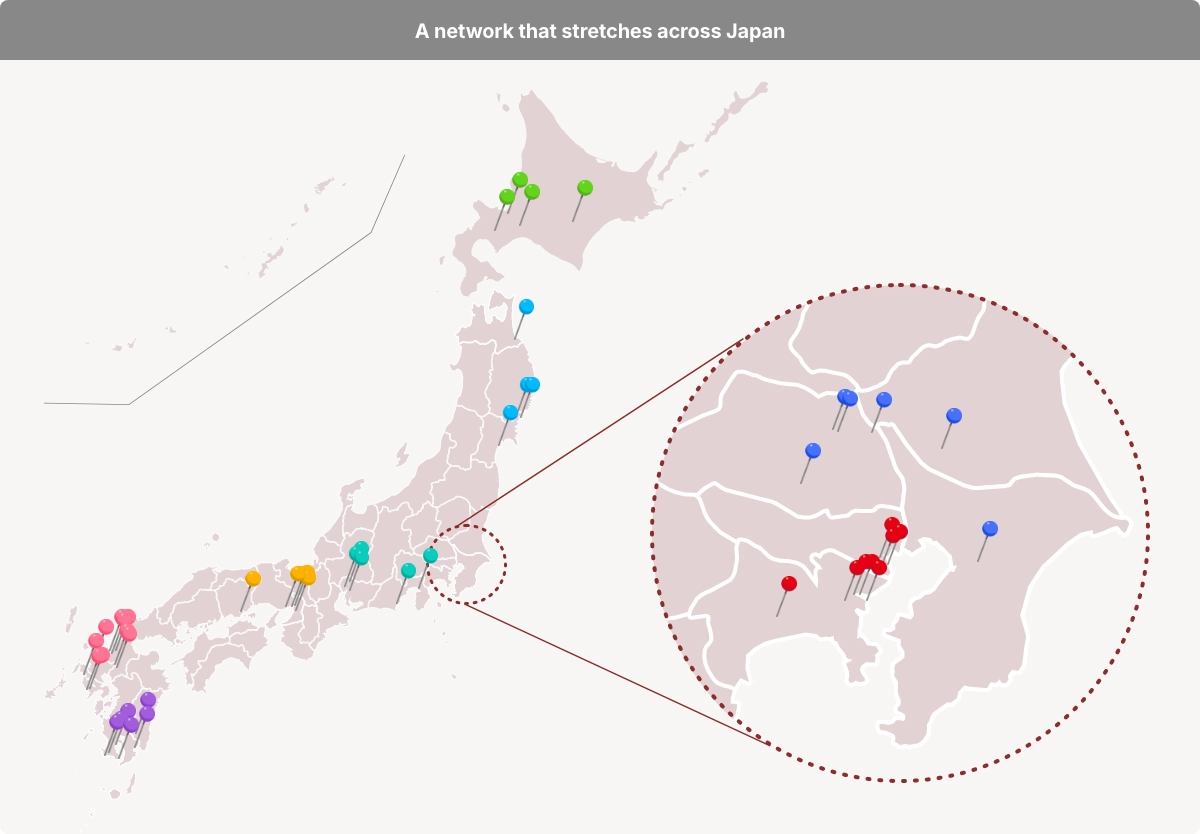

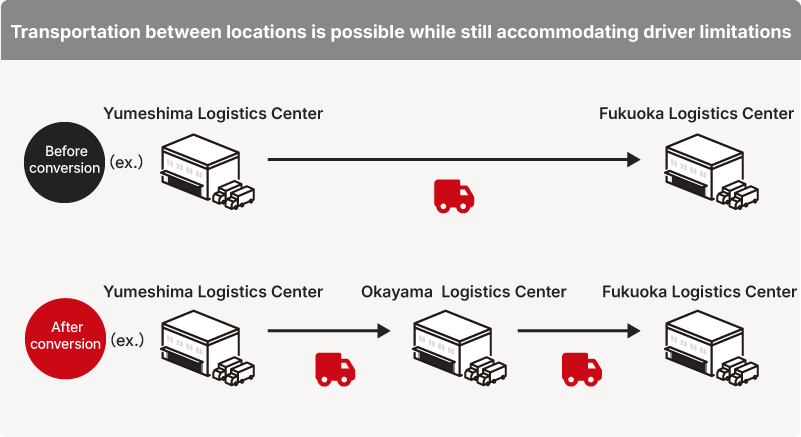

A network to meet logistics challenges

At our bases in Japan, YOKOREI provides "consolidated multi-distribution logistics," a service that combines the delivery center functions of an inventory-type distribution center (DC) a transit distribution center (TC).

This service allows customers such as food manufacturers and wholesalers to reduce transportation and labor costs, while also shortening transportation distances, cutting CO2 emissions, and helping to alleviate driver shortages.

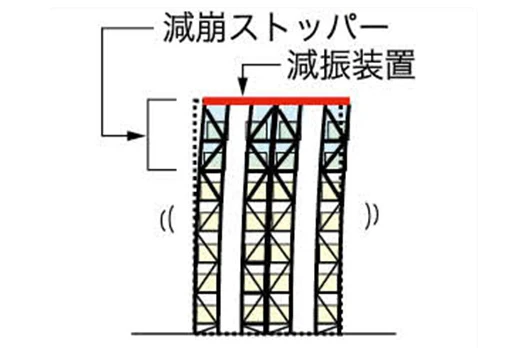

Seismic countermeasures for fully automatic rack warehouses

-

Vibration-Damping Rack -

Anti-Fall Stopper Rack

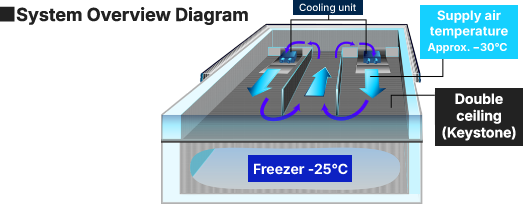

Natural convection cooling method ("Sittory")

Natural convection cooling is one of the key features of YOKOREI's refrigerated warehouses.

This method involves cooling the ceiling to create a natural convection current that refrigerates the entire warehouse, preventing uneven cooling and freezer burn.

As there is extremely minimal variation in temperature, natural convection cooling method is able to maintain products at their optimal quality and has been introduced at many of our centers.

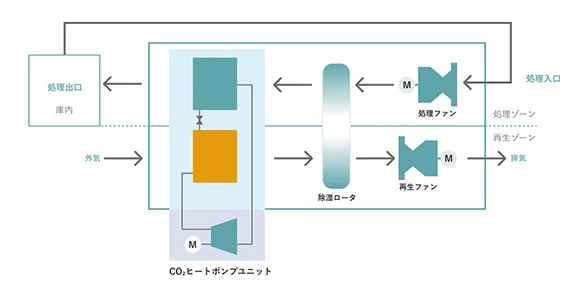

Desiccant Positive-pressure Air Conditioning System

Positive pressure is created by sending cooled air into the cargo handling room, preventing warm air, dust, and insects from entering, and also preventing condensation on cargo.

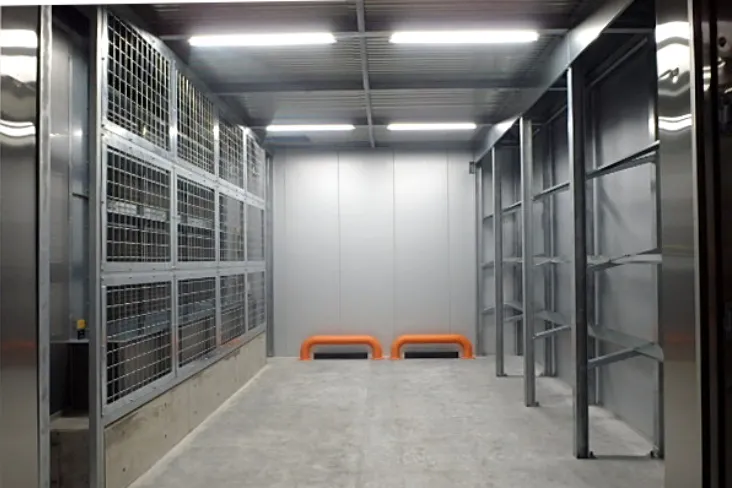

Cargo Navigation System with Electric Movable Racks

Our cargo navigation system, which can be easily operated with a tablet, displays cargo storage locations and efficient pickup routes. This has allowed us to realize a swift and accurate system that enables us to carry out detailed lot management while also significantly reducing the amount of time required for warehouse operations such as loading and unloading, as well as picking work.

This has created an environment in which even inexperienced employees can work accurately, without hesitation, and in a short amount of time.

Optimal storage environments for each type of food product

-

Semi-ultralow temperature freezers Our semi-ultralow temperature warehouses maintain product quality using a ceiling hairpin coil cooling method that is gentle on the stored cargo.

We provide a storage environment that is optimally suited to the food products within. -

A diverse range of chilled storage YOKOREI has installed chilled storage equipment to preserve the freshness and quality of agricultural products, dairy products, and other goods. We have enabled stable refrigeration in the range of 2–10ºC, providing an optimal environment for storing each type of product.

-

Quick freeze storage Our warehouses include frozen storage areas offering high-performance cooling that can reduce the temperature instantaneously.

This enables us to provide quick freezing that preserves the quality of marine, livestock, and agricultural products.

Ensuring smooth cargo delivery

Truck Reservation System

Customers can reserve arrival times through a computer or smartphone, and we guide trucks to the correct berth through text messages.

The latest system for optimal energy management

Building Energy Management System (BEMS)

With the introduction of BEMS, we have realized the visualization of electricity consumption in our refrigerated warehouses. This system enables us to check electricity consumption and operating hours for cooling systems, forklift chargers, lighting, air conditioners, etc.

Food defense measures that ensure safety and reliability

Building Entry/Exit and Surveillance Camera Systems

We have adopted a card authentication system used to control access to and from refrigerated warehouses.

In addition, surveillance cameras are installed inside and outside refrigerated warehouses to prevent accidents and theft.